Two (2) aspects of Hydrogen embrittlement;

Intergranular fracture and;Material selection.

Jason Amiri:

In this post, I discuss Hydrogen embrittlement, Intergranular fracture and Material selection.

What You Need to Know.

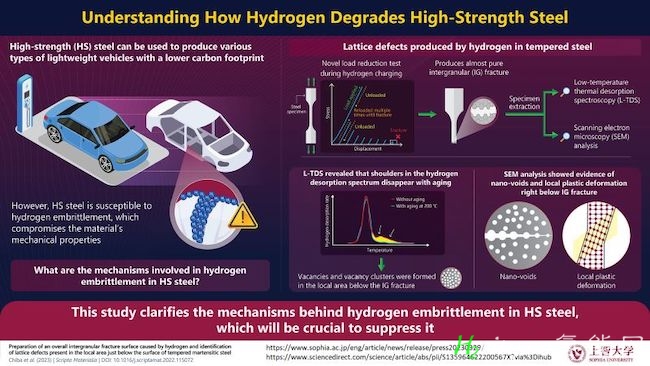

1. Hydrogen embrittlement in High-Strength (HS) steel results in intergranular (IG) fractures.

2. An overall intergranular (IG) fracture surface designed in a load reduction test and examined by low-temperature thermal desorption spectroscopy (L-TDS).

3. The goal was to explain the atomic scale lattice flaws in the local area just below the surface of a hydrogen-induced IG fracture in tempered martensitic steels.

4. Local plasticity and nano-voids watched on and near the prior austenite grain boundaries using electron backscatter diffraction (EBSD) and electron channelling contrast imaging (ECCI).

5. These findings indicate that local plastic deformation and its vacancy formation play a vital role in hydrogen-induced IG fracture in tempered martensitic steel.

ASME B31.12 Hydrogen Embrittlement

1. Hydrogen Embrittlement is the loss of a metal's ductility resulting from hydrogen absorption.

2. The most known and technologically significant trend for structural metals is that vulnerability to hydrogen embrittlement increases as the material strength increases.

3. Since the effect of materials strength on fracture in hydrogen gas can be so intense, all structural designs for hydrogen gas service should specify minimum yield strength and maximum yield strength for managing hydrogen embrittlement.

4. Examples of steels that have been established for hydrogen gas service are conventional ASTM A106 Grade B, ASTM A53 Grade B, and API 5L Grades X42 and X52 (PSL2 grades preferred), as well as microalloyed API 5L Grade X52.1.

5. ASME B31.12 recommends API 5L PSL2 Grades X42 and X52 for hydrogen gas service.

6. Microalloy versions of X42 and X52 grades enhance resistance to hydrogen embrittlement.

7. Hydrogen-assisted fracture tends to be reduced at elevated temperatures. For carbonsteel, however, hydrogen attack becomes an essential consideration above 200°C (392°F).

8. Alloying elements such as carbon, manganese, sulphur, phosphorus, and chromium give greater susceptibility to hydrogen embrittlement in low-alloysteel.

?Does ASME B31.12 suggests using API 5L PSL2 Grades X42 and X52 for hydrogen gas service?

Share your thoughts on hydrogen embrittlement in the comment section below.

氢脆的两个方面;

晶间断裂;

材料选择。

在这篇文章中,我讨论了氢脆、晶间断裂和材料选择。

你需要知道的。

1. 高强度 (HS) 钢中的氢脆导致晶间 (IG) 断裂。

2. 在减载试验中设计并通过低温热解附光谱 (L-TDS) 检查的整体晶间 (IG) 断裂面。

3. 目的是解释回火马氏体钢中氢诱导的IG断裂表面正下方局部区域的原子尺度晶格缺陷。

4. 使用电子背散射衍射 (EBSD) 和电子通道对比成像 (ECCI) 观察先前奥氏体晶界上和附近的局部塑性和纳米空隙。

5. 这些结果表明,局部塑性变形及其空位形成在回火马氏体钢氢诱导中空裂中起着至关重要的作用。

ASME B31.12 氢脆

1. 氢脆是由于氢吸收导致金属延展性的损失。

2. 结构金属最著名和技术上最重要的趋势是,随着材料强度的增加,对氢脆的脆弱性增加。

3.由于材料强度对氢气断裂的影响可能如此强烈,因此所有氢气工况的结构设计都应指定最小屈服强度和最大屈服强度以管理氢脆。

4. 已建立用于氢气应用的钢的例子是传统的 ASTM A106 B 级、ASTM A53 B 级和 API 5L 等级 X42 和 X52(首选 PSL2 等级),以及微合金化 API 5L 等级 X52.1。

5. ASME B31.12 推荐 API 5L PSL2 等级 X42 和 X52 用于氢气应用。

6. X42 和 X52 牌号的微合金版本增强了抗氢脆性。

7.氢辅助断裂在高温下趋于减少。然而,对于碳钢来说,氢侵蚀在200°C(392°F)以上成为必不可少的考虑因素。

8. 碳、锰、硫、磷和铬等合金元素在低合金钢中对氢脆的敏感性更高。

ASME B31.12 是否建议使用 API 5L PSL2 等级 X42 和 X52 进行氢气服务?

平台声明:该文观点仅代表作者本人,零碳未来网 系信息发布平台,我们仅提供信息存储空间服务。

发表评论 取消回复