Jason Amiri

This New Hydrogen Electrolyzer Could Make Hydrogen More Affordable and Sustainable.

Membrane-Free Hydrogen Electrolyzer (MFE): The Future of Hydrogen Production?

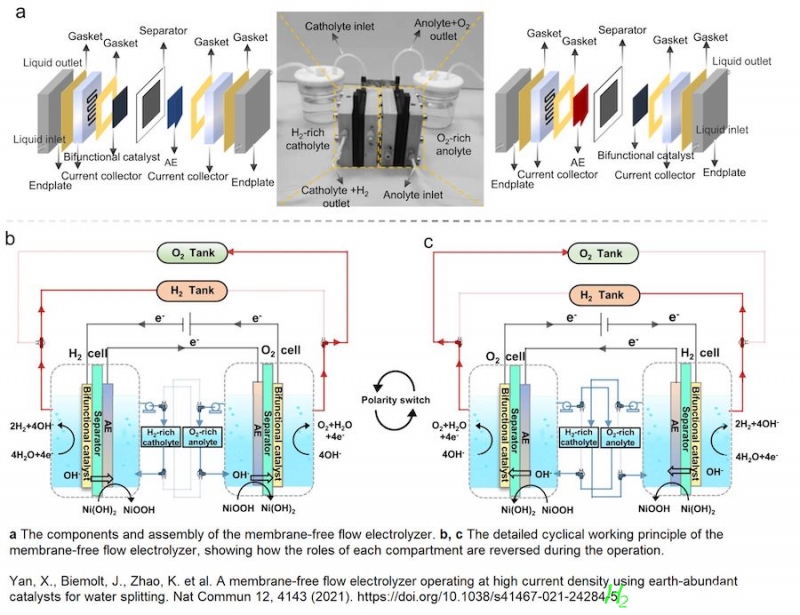

How Membrane-Free Hydrogen Electrolyzer (MFE) works:

1- The Membrane-Free Hydrogen Electrolyzer cell consists of two physically separated compartments connected by wires that enable the transfer of electrons for oxygen and hydrogen evolution reactions.

2- The anolyte and catholyte, which are O2-rich and H2-rich 1.0 M KOH solutions, respectively, flow continuously to their designated compartments during the reaction.

3- During the cycle where the left compartment serves as the cathode (refer to Fig. 1b), the bifunctional catalyst on the working electrode catalyzes the catholyte's hydrogen evolution reaction (HER). This HER generates OH- anions that migrate through the separator and react with Ni(OH)2 at the anode electrode (AE), forming NiOOH. The produced H2 gas is gathered in the H2 tank using a 3-way valve.

4- Meanwhile, the working Membrane-Free Hydrogen Electrolyzer electrode in the other compartment facilitates the oxygen evolution reaction (OER) in the anolyte by utilizing the OH- ions provided by transforming NiOOH into Ni(OH)2. The produced O2 is directed through another 3-way valve and into the O2 tank.

5- Calculated hydrogen electrolyser Faradaic efficiency = 96.5%.

FE = (n (gas) measured/ n (gas) calculated) = ((P.V (gas) measured / RT)/(Q/zF)

P = pressure (1 atm),

V = volume of the generated gas,

R = gas constant (8.314 J mol-1 K-1),

T = temperature (298 K),

Q = ∫Idt is the charge,

z = stoichiometric charge number (2 electrons per H2 molecule and 4 electrons per O2 molecule), and

F = Faraday constant (F = 96485.34 C mol-1).

Reference:

Yan, X., Biemolt, J., Zhao, K. et al. A membrane-free flow electrolyzer operating at high current density using earth-abundant catalysts for water splitting. Nat Commun 12, 4143 (2021).

? CPH2 Membrane-Free Hydrogen Electrolyser™ (MFE):

MODEL MFE220

Hydrogen Production [kg/day] = Up to 450

Oxygen Production [kg/day] = Up to 3,600

Gas Purity Hydrogen [%] = 99.57

Gas Purity Hydrogen with optional DeOxy Drier [%] = Up to 99.999

Gas Purity Oxygen [%] = Up to 99.8

Maximum Allowable Operating Pressure [barg] = 34

Water Consumption [L/hr] < 200 approx.

Input Water Quality [mg/L] (Potable) = 50 - 300

Stack Input Power [MW] = 1.0

Plant Efficiency [kWh/kg] <59

Input Voltage [VAC] = 400-415, @50Hz,3 phase

Weight (dry) [kg] = 29,500

Packaging 40ft container

Water inlet pressure [barg] = Up to 8

Control Siemens = PLC

Communication = Modbus/Ethernet

Operating Temperature (standard config.) [°C] = -10 to +35

Recommended Preventive Maintenance [Mths] = 6 & 12

Stack life [Yrs.] = 25

My posts reflect my personal perspective, knowledge, experience, and advice. Who are the other manufacturers of membrane-free electrolysers?

平台声明:该文观点仅代表作者本人,零碳未来网 系信息发布平台,我们仅提供信息存储空间服务。

发表评论 取消回复