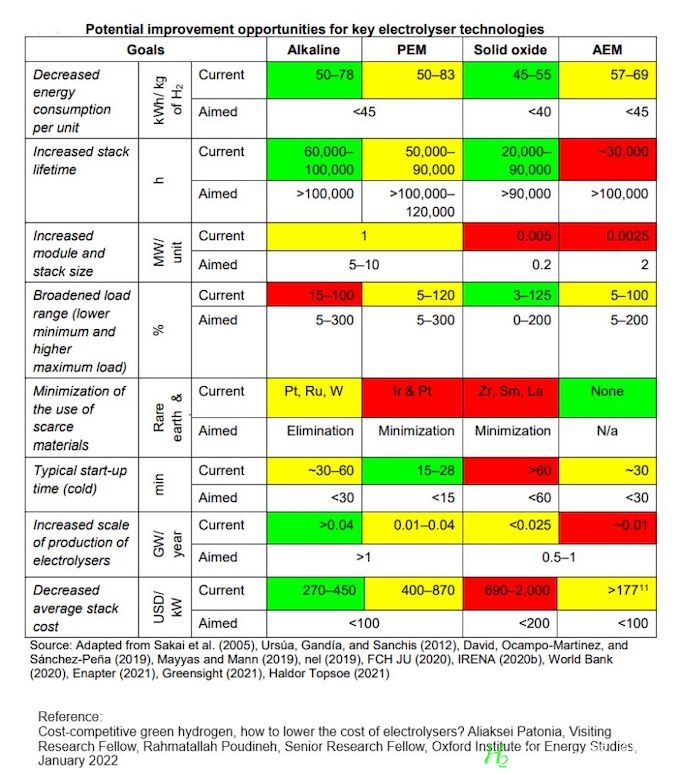

Hydrogen Electrolyzer Costs: What's Driving the Price Tag?

How can we reduce the cost of hydrogen electrolyzers?

(1) Stack:

(1-1) The hydrogen electrolyser stack consists of cell units, porous transport layers, bipolar plates, end plates, and smaller parts like spacers, seals, frames, and bolts.

(1-2) Stacks typically account for 40-60% of electrolyzer costs in alkaline and PEM hydrogen electrolyzers.

(1-3) Stacks make up 30% of the cost in solid oxide hydrogen electrolysers; in AEM hydrogen electrolysers, they account for 60%.

(2) Power electronics:

(2-1) Power electronics use solid-state electronics to control and convert electric power.

(2-2) The cost of power electronics in alkaline and PEM systems only makes up about 15% of the total cost.

(2-3) The cost of power electronics is higher at around 18% for AEM installations and around 30% for solid oxide electrolysers.

(3) Gas conditioning:

(3-1) Gas conditioning in electrolyzers involves mechanically compressing the gas and drying it to purify the raw hydrogen.

(3-2) Gas conditioning accounts for around 15% of alkaline and AEM systems costs but only about 10% for PEM installations and 6% for solid oxide systems.

(4) Balance of plant:

(4-1) The term "balance of plant" refers to a collection of components that play a crucial role in energy production. These components include heat recovery and heat rejection equipment, pumps, valves, piping, control systems, safety systems, waste systems, air conditioning, power systems, etc.

(4-2) The cost of balance of plant components accounts for 15 and 20% of the total cost for conventional alkaline and PEM electrolysers, respectively.

(4-3) The cost of solid oxide electrolysers for the balance of plant is over twice that of PEM installations: 34% vs. 15%.

(4-4) Almost half of the costs (48%) for AEM electrolysers are due to the balance of plant, which is 2-3 times more expensive than in alkaline and PEM systems.

(5) Estimated component costs (USD/kW) for 1 MW electrolysers in 2019:

a- Alkaline Hydrogen Electrolyzer

- Stack Cost = 270–450

- Power Electronics = 81-135

- Gas conditioning = 81-135

- Balance of plant = 108-180

- Total = 540-900

b- PEM Hydrogen Electrolyzer

- Stack Cost=400-870

- Power Electronics=100-217.5

- Gas conditioning=67-145

- Balance of plant=100-217.5

- Total=667-1,450

c- Solid Oxide Hydrogen Electrolyser

- Stack Cost = 690-2,000

- Power Electronics = 690-2,000

- Gas conditioning = 140-400

- Balance of plant = 780-2,267

- Total = 2,300-6,667

d- AEM Hydrogen Electrolyser

- Stack Cost=>177

- Power Electronics~167.5

- Gas conditioning~139.5

- Balance of plant~447

- Total=>931

Reference:

Cost-competitive green hydrogen, how to lower the cost of electrolysers? Aliaksei Patonia, Visiting Research Fellow, Rahmatallah Poudineh, Senior Research Fellow, Oxford Institute for Energy Studies, January 2022

平台声明:该文观点仅代表作者本人,零碳未来网 系信息发布平台,我们仅提供信息存储空间服务。

发表评论 取消回复