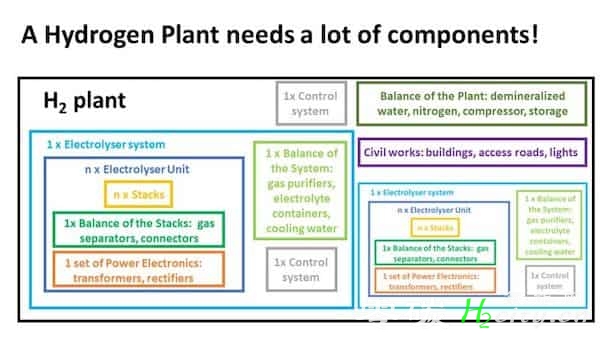

In order to achieve our plans regarding hydrogen production, large hydrogen plants need to be built. Sizes from a few MWs to even some GWs will be needed depending on the off-taker (i.e. refineries, steel, fertilizers, etc…). We put a lot of focus on the electrolyzers as a key piece, mainly in the stack of these electrolyzers, and it is, but there are many other components key to obtain working green hydrogen plants. The picture below shows the main components that a hydrogen plant made of two electrolysis system would have:

① Electrolysis system(s). Depending of the size of the hydrogen plant, one or several systems could be installed. These systems are already very complex, with many different components such as the stack, the balance of the stacks, the power electronics, the balance of the system or the control system.

② Balance of the Plant. In order to have a working hydrogen plant, extra equipment needs to be installed in order to operate effectively the different electrolyzer systems. This can include equipment related to the demineralized water, nitrogen supply, compressors, etc…

③ Civil works. A hydrogen plant is a quite large industrial area where buildings, access roads or light need to be installed.

④ Control system. Digitalization is key to have a modern hydrogen plant and to have a safe production of hydrogen.

DISCLAIMER: Not every component is included so use the comments to add the ones missing.

平台声明:该文观点仅代表作者本人,零碳未来网 系信息发布平台,我们仅提供信息存储空间服务。

发表评论 取消回复